Practical solutions for corrosion control from the best chemists in the industry….

See what this solution can do for you.

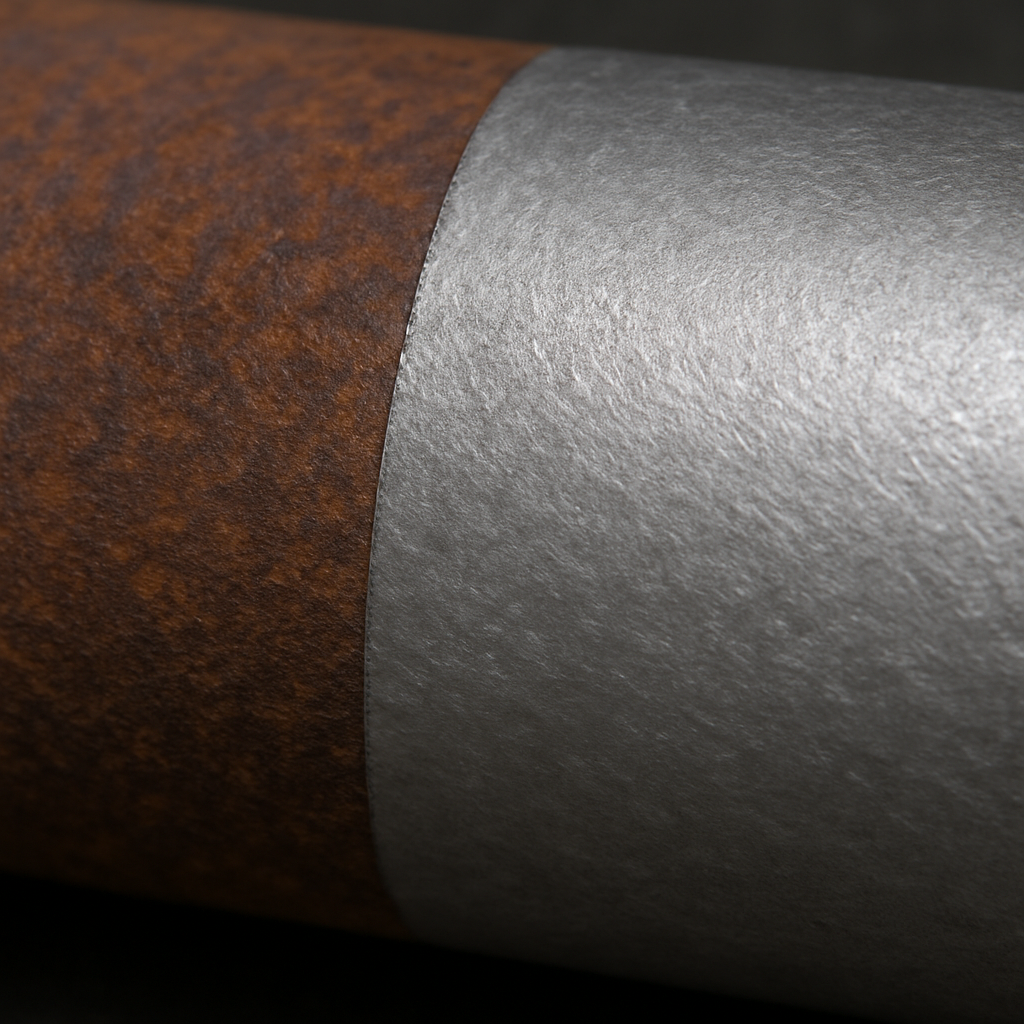

Protecting metal from rust is a ritual, much like tending to a well-loved iron pan.

Allied Shipping and Chemicals: Tailored Chemistry for the Oil and Offshore Industry

Allied Shipping and Chemicals has developed a specialized line of corrosion inhibitors specifically engineered for the challenging environments of oilfields and offshore facilities. The company’s proprietary formulations address not only general corrosion but also localized forms like pitting, under-deposit corrosion, and stress-corrosion cracking.

What Sets Allied’s Chemistry Apart?

Multi-functional Systems

Their advanced inhibitors are designed not just to prevent corrosion but also to act as biocides and scale preventers—reducing the need for multiple treatment chemicals and simplifying maintenance schedules.

Hydrocarbon Compatibility

Their film-forming amine-based inhibitors are fully compatible with crude oil, condensates, and gas lines. They protect internal pipeline walls without affecting fluid properties or downstream separation processes.

Thermally Stable Formulations

Offshore assets like risers and subsea equipment often face extreme temperature fluctuations. Allied’s inhibitors maintain film integrity even at high temperatures, ensuring consistent protection.

H2S and CO2 Resistance

Sour gas fields are notorious for aggressive corrosion. Allied’s products contain scavengers and complexing agents that neutralize H2S and CO2 impacts, prolonging the integrity of steel assets.

Environmentally Compliant

In offshore environments where discharge regulations are stringent, Allied’s products meet international environmental standards (such as OSPAR), ensuring efficacy without ecological harm.

Autonomous Proportioner for Efficient, Waste-Free Corrosion Inhibitor Dosing

Allied’s chemical proportioner offers precise, automatic dosing of corrosion inhibitors based on application-specific flow rates, ensuring optimal protection without overuse. Fully autonomous and requiring no external power or air supply, it operates reliably in remote or off-grid locations—ideal for oilfields and offshore sites. By delivering consistent inhibitor concentrations, it maximizes efficiency, minimizes chemical wastage, and reduces operational costs. The proportioner adjusts dosing in real time, responding to flow variations to maintain target inhibitor levels. This smart, self-regulating system ensures that corrosion control remains effective and economical, enhancing asset life while supporting environmentally responsible chemical management.

Stop Paying for Spray and Shine — Invest in Real Protection

Many industrial solvents feel like they’re doing the job—wetting the surface, adding shine—but in reality, they contain very little active ingredient. You end up wasting money on large volumes that offer minimal protection. It’s a false sense of security. In contrast, CI 80 from Allied is a highly concentrated corrosion inhibitor engineered for real results. Just a small amount delivers long-lasting protection, especially for exposed metal surfaces. It’s proven, effective, and costs a fraction—often just a tenth—of what you’d spend on those flashy, underperforming cans. Why waste money on volume when you can invest in performance with CI 80?

Workshop Application

Corrosion inhibitors play a critical role during the testing and external spraying stages of industrial maintenance, especially in sectors like oil and gas, infrastructure, and heavy equipment. When components such as pipes, valves, and structural metals undergo hydro-testing or pressure testing, they are exposed to water or other fluids that can rapidly accelerate corrosion. Injecting a corrosion inhibitor into the test fluid helps form a protective film on the metal surface, preventing oxidation and corrosion during and after the test, even if moisture remains inside the system.

For external applications, corrosion inhibitors are sprayed directly onto the metal surfaces, especially in exposed environments. These inhibitors act as a barrier between the metal and atmospheric moisture, oxygen, or contaminants like salt. Spraying is commonly done using low-pressure sprayers or automated systems to ensure uniform coverage. This step is vital for idle equipment, pipelines, and metal structures that may sit in open yards or coastal areas. The inhibitor helps prevent flash rusting and long-term degradation, extending the lifespan of the asset.

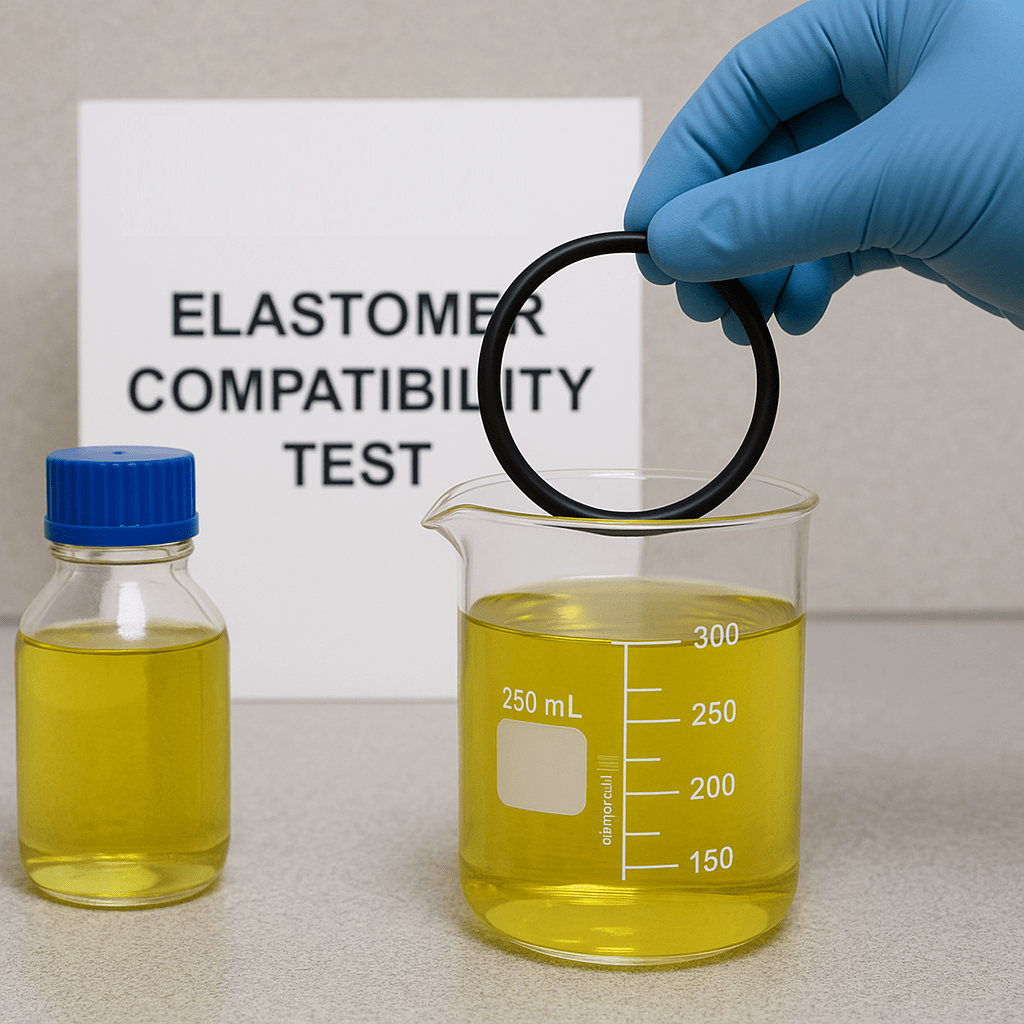

Ensuring Elastomer Compatibility Through Rigorous Testing

Allied conducts controlled lab tests by immersing elastomer samples in process fluids at simulated field temperatures and durations. Physical changes like swelling, cracking, or hardening are closely monitored. This ensures seals and gaskets used in pipelines, pumps, and tanks remain reliable and resistant to chemical attack.

Corrosion Prevention – Myths

Different Types of Corrosion Inhibitors & How They Work

Anodic Inhibitors

These inhibitors work by forming a protective oxide film over the metal’s surface, thereby slowing down the anodic reaction (metal oxidation). They are effective in systems where oxygen or other oxidizing agents are present. For instance, sodium chromate and zinc salts are commonly used in closed-loop cooling systems and water-based pipelines.

Cathodic Inhibitors

These slow down the cathodic reaction, which often involves the reduction of oxygen or hydrogen evolution. Cathodic inhibitors like calcium, magnesium salts, or certain polyphosphates create a barrier layer over the cathodic sites, impeding further reactions.

Mixed Inhibitors

These offer protection at both anodic and cathodic sites, making them highly versatile for systems that don’t allow pinpoint control of corrosion processes. Examples include phosphates, silicates, and organic inhibitors like amines and azoles.

Volatile Corrosion Inhibitors (VCIs)

Commonly used in enclosed spaces like pipelines, VCIs sublimate into the air and then condense on metal surfaces to form a protective molecular layer. They are often used during shipment or storage of machinery and spare parts.

Film-forming Inhibitors

These include surfactants and fatty amines that physically adhere to metal surfaces, especially in hydrocarbon systems. They are ideal for oil pipelines and fuel tanks, where they reduce corrosion by creating a hydrophobic barrier.

How Corrosion Prevention Techniques Are Applied

Rust prevention in industrial applications goes beyond just applying a chemical—it is a comprehensive process. A few common methods include:

Vapor Phase Protection

Particularly relevant in offshore applications, where equipment is idle or stored, VCIs can be deployed to prevent corrosion even in confined, salt-laden airspaces.

Surface Treatment & Passivation

Cleaning rusted surfaces mechanically (grinding or blasting), followed by the application of passivating agents to suppress further oxidation.

Inhibitor Injection in Flow Lines

For pipelines, especially in oil production, inhibitors are injected directly into the fluid stream. Continuous dosing ensures a protective film remains throughout the internal surface of the line.

Coatings with Embedded Inhibitors

Paints and coatings used on rigs or storage tanks may contain embedded corrosion inhibitors that activate upon moisture exposure, providing long-term protection.

Hydrotesting Additives

During pressure testing of pipes or vessels using water, corrosion inhibitors are added to the hydrotest fluid to prevent flash corrosion post-drainage.

Prolonging Asset Life and Reducing Downtime

By integrating these tailored chemistries into ongoing operations, Allied Shipping and Chemicals helps clients:

Reduce overall cost of ownership for infrastructure operating in some of the most demanding conditions on earth.

Extend asset life of platforms, pipelines, tanks, and equipment.

Minimize unplanned downtime due to leaks or corrosion failures.

Optimize inspection intervals by maintaining consistently protected surfaces.

What matters most for your equipment?

In industries where uptime is critical and corrosion is inevitable, the right chemistry can be the most powerful line of defense. Through its innovative and specialized solutions, Allied Shipping and Chemicals empowers oilfield operators and offshore facilities to fight corrosion smarter—not harder—and ensure their assets last longer, operate safer, and perform better.